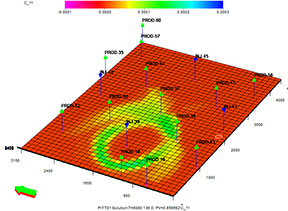

Ultimate EOR staff have experience assisting in field scale tracer test implementation. The presence of skilled staff on site during the injection and sampling phases of tracer tests helps ensure appropriate chemicals are injected in every phase and the sample collection procedure is adequate. The staff can assist in all tracer tests, including single well EOR pilots and partitioning inter-well tracer tests.